- Campus water, power management

- Solar power

- Remote monitoring of assets

- Building Blocks

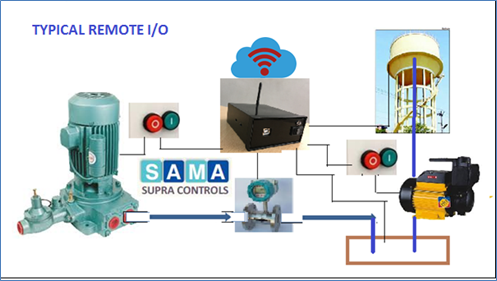

- Remote I/O

- Network

- Central Unit with internet connectivity & display

- Historian & HMI (optional)

- Reports

- Remote I/O

- Example applications for these are Borewell / sump / overhead tank. These Remote I/Os are based on IIoT technology.

- Accessories for Remote I/O

- Auto/Manual stations: For each device such as motor or for group of Road lighting, this may be required.

- In Manual, local start / stop buttons can be used. When in Auto motor start / stop will be from the Remote I/O.Position of Auto / Manual station can be monitored from Central Unit.

- Relay interface: For contacts to be wired up with Auto/Manual stations or Motor starters, a relay interface has to be used with each Remote I/O unit. It can be in a separate enclosure or same enclosure with the Remote I/O unit, depending on the contact rating required.

- Additional instrumentation: Flowmeter at discharge of pumps, Level measurement at sumps and overhead tanks, current meters, gen set status can all be connected to Remote I/O units.

- Network

- Wireless LAN adaptor: IIoT adaptor with Antenna. This is used for communication between Remote I/O and Central Unit.

- Sometimes, when RF signal is weak, it is also used to form a bridge between two adaptors, like a wifi extender.

Central Unit

- This is based on IIoT processors. For viewing over internet, internet connectivity is required. Local display can be connected via inbuilt HDMI interface.

- Remote Monitoring

- Motor Runing Status

- Auto / manual switch position

- Bore well discharge flow

- Current indication etc

- Remote Control

- Motor on / off while in Auto, scheduled on / off,on / off of motors based on sump or OH tank level.

- Scheduled Lighting on/ off

- Equipment (motor, spray, heater etc) protection

- Trip on low discharge.

- Trip on high current

- Trip on ambient conditions, etc

Historian

- SAMA Real Time Process Historian features include data from multiple data sources, large tag capacity & Database. Supports multiple concurrent users. Calculations required for production reports are provided as standard feature. Seamlessly connects to RT viewer, web server as well as other applications. It caters to all - oil & gas, minerals & mining, power & distribution, pharma & food; production, storage & distribution.

- Functional Specifications of Historian

- Data Source – Redundant OPC sources, ODBC, Files, industrial protocols

- Structured data storage – Parameter, tag, group, equipment, area, unit, Plant

- Scaling, Eng Units, quality

- Data compression - With or without dead-band; remove repeat values

- Short term & long term recording - RT trends and history

- Alias on integers

- Automatic Snapshots of multiple tags based on specific tags and conditions - multiple tags

- Automatic setting of process parameters based on process conditions

- Trigger based on certain tags and conditions – trigger user exe

- Query builder – logical operation with multiple tags- can be used for optimisation and reports

- Detect Batch conditions and take snapshots

- Adv Calc – Max, Min, Ave, ROC, Deviation, Totalizer, sum, statistical, incremental values

- Licensing based on Tag count – 500, 3000, 10000, 30000, 100000, 100000+

SAMA Web Client

- Unique web client combines process data, batch data, Alarms & events as well as reports.

- This comprises of Dynamic data grids, multi-pen trends, KPI gadgets as well as Report views

- Apart from displaying process data, user can directly trend a variable and see its alarm occurrences by click of the mouse.

- Multiple user levels are provided to ensure only authorised access takes place.

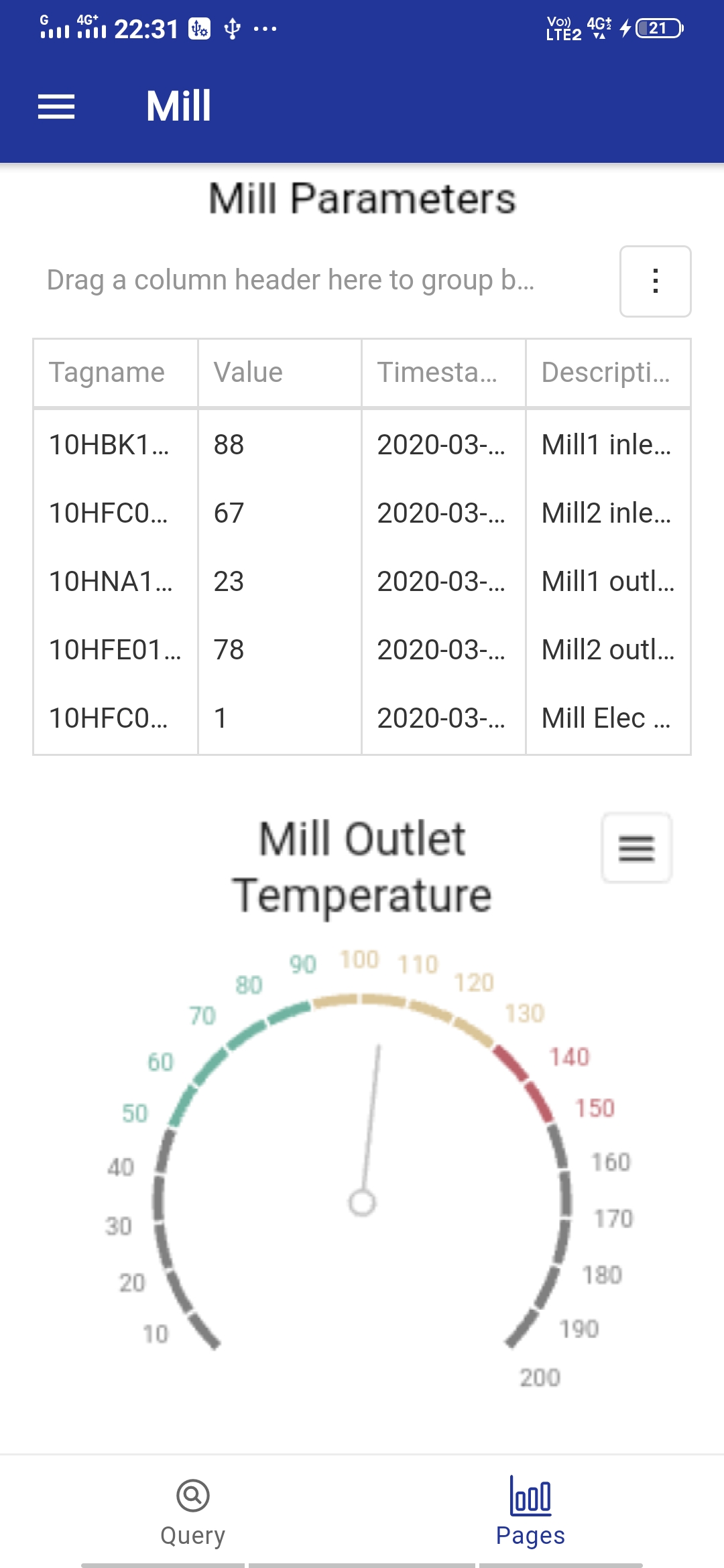

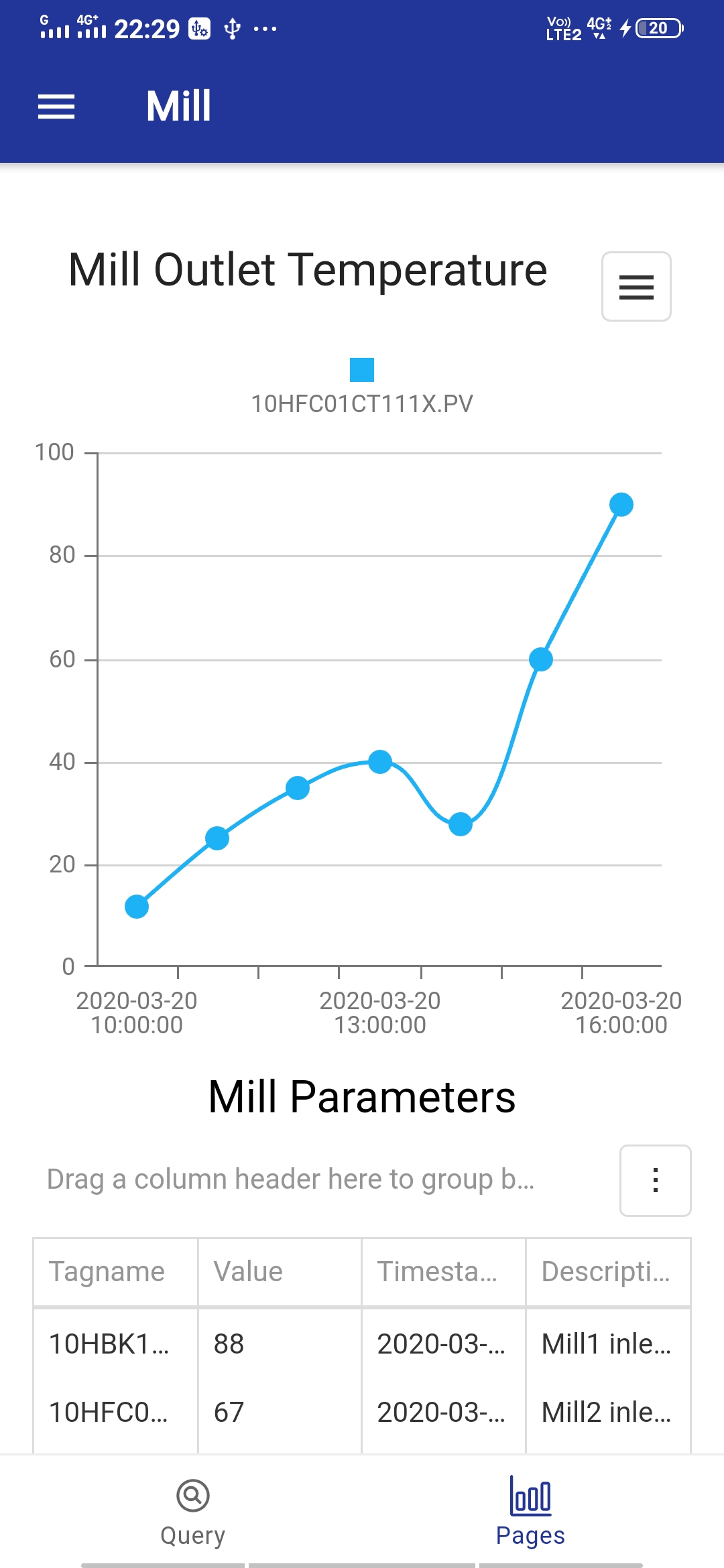

SAMA Mobile App sample displays